Before starting to look for the ball-bearing you need, it is wise to get more information about this tiny kind of product. Let’s check our review to ensure you to make the perfect choice.

What are ball-bearings?

A ball-bearing is a rolling-element bearing that uses balls to maintain the separation between the bearing races and so to reduce the rotational friction. It is also supporting radial and axial loads to ensure a perfectly secure and performant rolling-element.

Ball-bearings are used and can be found in a wide range of markets such as aerospace industry, automotive and heavy goods vehicles (OEM), automotive aftermarket, heavy duty aftermarket, cement work, wind energy, rail, mining, quarrying, industrial distribution, equipment construction, steel industry, agricultural industry, machine tool and universal industrial solutions in general.

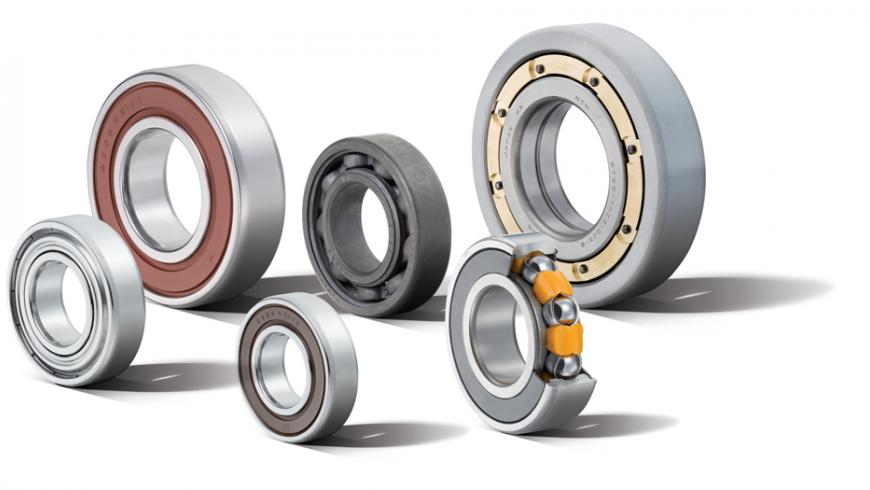

Ranges of ball-bearings

There are a lot of ball-bearing ranges on the market – because it is used in a widely different type of industries.

In that case, ball-bearings offer a tremendous choice of options: materials, heat treatment, sealing, angle of contact, diameter of the product… In fact, bore diameters start from 1.5 millimeters to 1.32 millimeters for a very precise and tiny artefact.

Without mentioning these options, different types of ball-bearings are available:

- Deep-groove ball-bearings (available in 1.32 millimeters)

- Double-row radial contact bearings

- Single-row angular contact bearings (with 4 points of contact in different angles)

- Double-row angular contact bearings (with a 25° angle)

- Self-aligning ball-bearings

- Thrust ball-bearings

- Insert thrust bearings

- Instrumented ball-bearings

- Individual ball-bearings

- Spherical roller bearings

- Tapered roller bearings

- Cylindrical roller bearings

- Needle roller bearings

- High precision bearings

It is then easy to find the best one for your industry.

Where to find the ball-bearings you need

Few engineering industries are manufacturing ball-bearings. To get the exact type needed, a given company has to choose wisely which partner it wants to work with.

To make the perfect choice and select the best manufacturer, it is mandatory to compare the different offers on the market. Some industries have wider ranges of ball-bearings and other ones are more specialized on a one-type product. In each case, finding the better quality is the highest purpose of this kind of benchmark.

A great and trustworthy partner will offer you to choose from a wide range of options such as the materials, the heat and surface treatment of the ball-bearing, the cages, the type of sealing (shields, contact seals, low torques seal, non-contact seals…), the angle of contact, the internal clearance, the preload, the lubrication-type, the pairing system, the type of bore (conical or cylindrical) or the enlargement of the inner ring.

Don’t hesitate to reach out the companies you found to access more details about the manufacturers and their products.